|

|

|

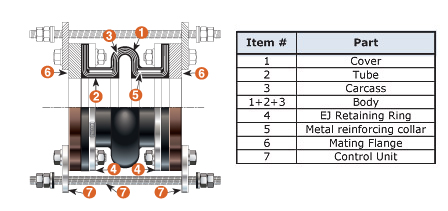

Rubberexpansionjoint.com ST Style molded rubber expansion joints are designed with a metal reinforcing collar molded into the necks of the carcass. This allows the ST style to use light weight split retaining rings (sold separately) to back-up the molded integral rubber flange that is molded into the ST. The ST style is also available in a filled arch design know as style STF. The ST can be made custom with multiple arches to improve movement, non standard flanges or enlarge flange type (different size flanges on each end), non standard lengths, as a reducer type, or with permanent offsets built into the joint. Larger sizes are available on request. The ST and STF are available on request to meet the requirements of the U.S.C.G. The STF style or filled arch will reduce allowable movements by 50%. It will also increase spring rates by 4 times that of the ST style. The filled arch design is a great option to reduce turbulence and eliminates the ability of solids to settle and remain in the arch. The “filler” in the filled arch is made from a low durometer soft rubber material that is bonded to the ID of the traditional arch. The ID of the STF has a one piece seamless inner tube eliminating the ability of the filler to come loose in service.

|

|

|

SPOOL TYPE (ST)

|

|

Dimensions

|

|

Movement Distance

|

Operating Condition

|

Weight (LBS)

|

|

Pipe Size

|

O'all Length

|

Flange OD

|

Bolt Circle

|

No. of Bolt Holes

|

Bolt Hole Size

|

Retaining Ring Thickness

|

Axial Compression

|

Axial Extension

|

Lateral Deflection

|

Angular Deflection

|

Max w.p. (psi)-3,-4

|

Max Vacuum

(in. of Hg)-5

|

Exp. Joint + Retaining Ring = Total

|

Control Unit

(2 Rod)-1,-2

|

|

2"

|

6"

|

6"

|

4 3/4"

|

4

|

3/4"

|

3/8"

|

7/16"

|

1/4"

|

±1/2"

|

19°

|

150

|

26

|

8.0+3.50=11.50

|

6.75

|

|

2 1/2"

|

6"

|

7"

|

5 1/2"

|

4

|

3/4"

|

3/8"

|

7/16"

|

1/4"

|

±1/2"

|

15°

|

150

|

26

|

11.5+5.50=17.00

|

7.50

|

|

3"

|

6"

|

7 1/2"

|

6"

|

4

|

3/4"

|

3/8"

|

7/16"

|

1/4"

|

±1/2"

|

13°

|

150

|

26

|

13.0+5.75=18.75

|

7.75

|

|

4"

|

6"

|

9"

|

7 1/2"

|

8

|

3/4"

|

3/8"

|

7/16"

|

1/4"

|

±1/2"

|

10°

|

150

|

26

|

16.0+7.00=23.00

|

7.00

|

|

5"

|

6"

|

10"

|

8 1/2"

|

8

|

7/8"

|

3/8"

|

7/16"

|

1/4"

|

±1/2"

|

8°

|

150

|

26

|

19.0+7.75=26.75

|

7.50

|

|

6"

|

6"

|

11"

|

9 1/2"

|

8

|

7/8"

|

3/8"

|

7/16"

|

1/4"

|

±1/2"

|

6°

|

150

|

26

|

21.0+9.00=30.00

|

8.50

|

|

8"

|

6"

|

13 1/2"

|

11 3/4"

|

8

|

7/8"

|

3/8"

|

11/16"

|

3/8"

|

±1/2"

|

6°

|

150

|

26

|

29.0+15.75=44.75

|

11.25

|

|

10"

|

8"

|

16"

|

14 1/4"

|

12

|

1"

|

3/8"

|

11/16"

|

3/8"

|

±1/2"

|

5°

|

150

|

26

|

45.0+16.25=61.25

|

24.50-1

|

|

12"

|

8"

|

19"

|

17"

|

12

|

1"

|

3/8"

|

11/16"

|

3/8"

|

±1/2"

|

5°

|

150

|

26

|

62.0+22.75=84.75

|

26.00-1

|

|

14"

|

8"

|

21"

|

18 3/4"

|

12

|

1 1/8"

|

3/8"

|

11/16"

|

3/8"

|

±1/2"

|

4°

|

150

|

15

|

75.0+27.00=102.00

|

31.00-1

|

|

16"

|

8"

|

23 1/2"

|

21 1/4"

|

16

|

1 1/8"

|

3/8"

|

11/16"

|

3/8"

|

±1/2"

|

4°

|

150

|

15

|

90.0+33.00=123.00

|

38.50-2

|

|

18"

|

8"

|

25"

|

22 3/4"

|

16

|

1 1/4"

|

3/8"

|

11/16"

|

3/8"

|

±1/2"

|

3°

|

150

|

15

|

92.0+36.50=128.50

|

41.00-2

|

|

20"

|

8"

|

27 1/2"

|

25"

|

20

|

1 1/4"

|

3/8"

|

13/16"

|

7/16"

|

±1/2"

|

3°

|

150

|

15

|

111.0+40.00=151.00

|

41.75-2

|

|

24"

|

10"

|

32"

|

29 1/2"

|

20

|

1 3/8"

|

3/8"

|

13/16"

|

7/16"

|

±1/2"

|

3°

|

150

|

15

|

145.0+48.00=193.00

|

58.75

|

|

SPOOL TYPE: FILLED ARCH (STF)

|

|

Dimensions

|

|

Movement Distance

|

Operating Condition

|

Weight (LBS)

|

|

Pipe Size

|

O'all Length

|

Flange OD

|

Bolt Circle

|

No. of Bolt Holes

|

Bolt Hole Size

|

Retaining Ring Thickness

|

Axial Compression

|

Axial Extension

|

Lateral Deflection

|

Angular Deflection

|

Max w.p. (psi)-3,-4

|

Max Vacuum

(in. of Hg)-5

|

Exp. Joint + Retaining Ring = Total

|

Control Unit

(2 Rod)-1,-2

|

|

2"

|

6"

|

6"

|

4 3/4"

|

4

|

3/4"

|

3/8"

|

7/32"

|

1/8"

|

±1/4"

|

9.5°

|

150

|

26

|

9.0+3.50=12.50

|

6.75

|

|

2 1/2"

|

6"

|

7"

|

5 1/2"

|

4

|

3/4"

|

3/8"

|

7/32"

|

1/8"

|

±1/4"

|

7.5°

|

150

|

26

|

12.5+5.50=18.00

|

7.50

|

|

3"

|

6"

|

7 1/2"

|

6"

|

4

|

3/4"

|

3/8"

|

7/32"

|

1/8"

|

±1/4"

|

6.5°

|

150

|

26

|

14.5+5.75=20.25

|

7.75

|

|

4"

|

6"

|

9"

|

7 1/2"

|

8

|

3/4"

|

3/8"

|

7/32"

|

1/8"

|

±1/4"

|

5°

|

150

|

26

|

17.5+7.00=24.50

|

7.00

|

|

5"

|

6"

|

10"

|

8 1/2"

|

8

|

7/8"

|

3/8"

|

7/32"

|

1/8"

|

±1/4"

|

4°

|

150

|

26

|

21.0+7.75=28.75

|

7.50

|

|

6"

|

6"

|

11"

|

9 1/2"

|

8

|

7/8"

|

3/8"

|

7/32"

|

1/8"

|

±1/4"

|

3°

|

150

|

26

|

23.0+9.00=32.00

|

8.50

|

|

8"

|

6"

|

13 1/2"

|

11 3/4"

|

8

|

7/8"

|

3/8"

|

11/32"

|

3/16"

|

±1/4"

|

3°

|

150

|

26

|

32.0+15.75=47.75

|

11.25

|

|

10"

|

8"

|

16"

|

14 1/4"

|

12

|

1"

|

3/8"

|

11/32"

|

3/16"

|

±1/4"

|

2.5°

|

150

|

26

|

49.5+16.25=65.75

|

24.50-1

|

|

12"

|

8"

|

19"

|

17"

|

12

|

1"

|

3/8"

|

11/32"

|

3/16"

|

±1/4"

|

2.5°

|

150

|

26

|

68.5+22.75=91.25

|

26.00-1

|

|

14"

|

8"

|

21"

|

18 3/4"

|

12

|

1 1/8"

|

3/8"

|

11/32"

|

3/16"

|

±1/4"

|

2°

|

150

|

15

|

82.5.0+27.00=109.50

|

31.00-1

|

|

16"

|

8"

|

23 1/2"

|

21 1/4"

|

16

|

1 1/8"

|

3/8"

|

11/32"

|

3/16"

|

±1/4"

|

2°

|

150

|

15

|

99.0+33.00=132.00

|

38.50

|

|

18"

|

8"

|

25"

|

22 3/4"

|

16

|

1 1/4"

|

3/8"

|

11/32"

|

3/16"

|

±1/4"

|

1.5°

|

150

|

15

|

101.5+36.50=138.00

|

41.00

|

|

20"

|

8"

|

27 1/2"

|

25"

|

20

|

1 1/4"

|

3/8"

|

13/32"

|

7/32"

|

±1/4"

|

1.5°

|

150

|

15

|

122.5+40.00=162.50

|

41.75

|

|

24"

|

10"

|

32"

|

29 1/2"

|

20

|

1 3/8"

|

3/8"

|

13/32"

|

7/32"

|

±1/4"

|

1.5°

|

150

|

15

|

159.5+48.00=207.50

|

58.75

|

|

Size

|

100% EPDM

|

100% Neoprene

|

100% Butyl

|

Retaining Rings

|

Retaining Rings

|

Control Unit (Control Rods)

|

Control Unit (Control Rods)

|

|

Pipe

|

Part No.

|

Price

|

Part No.

|

Price

|

Part No.

|

Price

|

Carbon Steel Zinc Plated Part No.

|

Price (Set=4)

|

T-304

Part No.

|

Price (Set=4)

|

Carbon Steel Zinc Plated Part No.

|

Price (Set)

|

T-304

Part No.

|

Price (Set)

|

|

Open Arch

|

|

2"

|

|

$191.46 |

|

$180.82 |

|

$232.57 |

|

$10.17 |

|

$116.75 |

|

$32.88 |

|

$76.72 |

|

2 1/2"

|

|

$198.00 |

|

$187.00 |

|

$293.90 |

|

$12.21 |

|

$161.05 |

|

$33.96 |

|

$79.24 |

|

3"

|

|

$199.64 |

|

$188.55 |

|

$242.70 |

|

$17.79 |

|

$184.80 |

|

$33.96 |

|

$79.24 |

|

4"

|

|

$193.36 |

|

$182.61 |

|

$235.13 |

|

$20.34 |

|

$236.33 |

|

$33.96 |

|

$79.24 |

|

5"

|

|

$232.22 |

|

$220.26 |

|

$284.04 |

|

$24.42 |

|

$262.93 |

|

$33.96 |

|

$79.24 |

|

6"

|

|

$291.00 |

|

$274.83 |

|

$353.97 |

|

$25.41 |

|

$298.48 |

|

$38.67 |

|

$90.23 |

|

8"

|

|

$353.33 |

|

$333.70 |

|

$430.02 |

|

$34.89 |

|

$443.25 |

|

$43.71 |

|

$101.99 |

|

10"

|

|

$442.83 |

|

$417.28 |

|

$539.21 |

|

$45.15 |

|

$547.95 |

|

$72.78 |

|

$169.82 |

|

12"

|

|

$616.12 |

|

$580.58 |

|

$751.27 |

|

$68.64 |

|

$784.28 |

|

$83.25 |

|

$194.25 |

|

14"

|

|

$748.83 |

|

$718.87 |

|

$913.40 |

|

$88.89 |

|

$1,040.25 |

|

$107.46 |

|

$250.74 |

|

16"

|

|

$853.93 |

|

$819.77 |

|

$1,043.35 |

|

$111.87 |

|

$1,284.88 |

|

$167.46 |

|

$390.74 |

|

18"

|

|

$939.23 |

|

$901.66 |

|

$1,153.35 |

|

$157.62 |

|

$1,219.35 |

|

$190.26 |

|

$443.94 |

|

20"

|

|

$1,105.65 |

|

$1,061.42 |

|

$1,357.85 |

|

$186.42 |

|

$1,683.25 |

|

$190.26 |

|

$443.94 |

|

24"

|

|

$1,557.38 |

|

$1,495.08 |

|

$1,906.13 |

|

$223.74 |

|

$1,876.90 |

|

$228.18 |

|

$532.42 |

|

Filled Arch

|

|

2"

|

|

$214.05 |

|

$202.16 |

|

$259.75 |

|

$10.17 |

|

$116.75 |

|

$32.88 |

|

$76.72 |

|

2 1/2"

|

|

$221.04 |

|

$208.76 |

|

$267.55 |

|

$12.21 |

|

$161.05 |

|

$33.96 |

|

$79.24 |

|

3"

|

|

$223.32 |

|

$210.91 |

|

$271.12 |

|

$17.79 |

|

$184.80 |

|

$33.96 |

|

$79.24 |

|

4"

|

|

$216.32 |

|

$204.30 |

|

$262.65 |

|

$20.34 |

|

$236.33 |

|

$33.96 |

|

$79.24 |

|

5"

|

|

$261.17 |

|

$246.66 |

|

$317.57 |

|

$24.42 |

|

$262.93 |

|

$33.96 |

|

$79.24 |

|

6"

|

|

$325.63 |

|

$307.54 |

|

$395.52 |

|

$25.41 |

|

$298.48 |

|

$38.67 |

|

$90.23 |

|

8"

|

|

$395.51 |

|

$373.54 |

|

$480.64 |

|

$34.89 |

|

$443.25 |

|

$43.71 |

|

$101.99 |

|

10"

|

|

$495.85 |

|

$467.24 |

|

$602.84 |

|

$45.15 |

|

$547.95 |

|

$72.78 |

|

$169.82 |

|

12"

|

|

$690.46 |

|

$650.62 |

|

$840.42 |

|

$68.64 |

|

$784.28 |

|

$83.25 |

|

$194.25 |

|

14"

|

|

$872.28 |

|

$837.38 |

|

$1,061.55 |

|

$88.98 |

|

$1,040.25 |

|

$107.46 |

|

$250.74 |

|

16"

|

|

$996.00 |

|

$956.16 |

|

$1,213.85 |

|

$111.87 |

|

$1,284.88 |

|

$167.45 |

|

$390.74 |

|

18"

|

|

$1,099.83 |

|

$1,055.83 |

|

$1,346.05 |

|

$157.62 |

|

$1,219.35 |

|

$190.26 |

|

$443.94 |

|

20"

|

|

$1,294.80 |

|

$1,243.01 |

|

$1,584.85 |

|

$186.42 |

|

$1,683.25 |

|

$190.26 |

|

$443.94 |

|

24"

|

|

$1,818.95 |

|

$1,746.19 |

|

$2,220.03 |

|

$223.74 |

|

$1,876.90 |

|

$228.18 |

|

$532.42 |

|

U.S. COAST GUARD APPROVED: Unthreaded Bolt Holes

|

|

100% EPDM

|

|

Retaining Rings

|

Retaining Rings

|

Control Unit (Control Rods)

|

Control Unit (Control Rods)

|

|

SIZE

|

OPEN ARCH

|

Price |

FILLED ARCH

|

Price |

Zinc Plated

|

Price

|

T-304

|

Price

|

Zinc Plated

|

Price

|

T-304

|

Price

|

|

2"

|

|

$196.46 |

|

$219.05 |

|

$10.17 |

|

$116.75 |

|

$32.88 |

|

$76.72 |

|

2 1/2"

|

|

$203.00 |

|

$226.04 |

|

$12.21 |

|

$161.05 |

|

$33.96 |

|

$79.24 |

|

3"

|

|

$204.64 |

|

$228.32 |

|

$17.79 |

|

$184.80 |

|

$33.96 |

|

$79.24 |

|

4"

|

|

$198.36 |

|

$221.32 |

|

$20.34 |

|

$236.33 |

|

$33.96 |

|

$79.24 |

|

5"

|

|

$238.22 |

|

$266.17 |

|

$24.42 |

|

$262.93 |

|

$33.96 |

|

$79.24 |

|

6"

|

|

$296.00 |

|

$330.63 |

|

$25.41 |

|

$298.48 |

|

$38.67 |

|

$90.23 |

|

8"

|

|

$358.33 |

|

$400.51 |

|

$34.89 |

|

$443.25 |

|

$43.71 |

|

$101.99 |

|

10"

|

|

$447.83 |

|

$500.85 |

|

$45.15 |

|

$547.95 |

|

$72.78 |

|

$169.82 |

|

12"

|

|

$621.12 |

|

$695.46 |

|

$68.64 |

|

$784.28 |

|

$83.25 |

|

$194.25 |

|

14"

|

|

$753.83 |

|

$877.28 |

|

$88.98 |

|

$1,040.25 |

|

$107.46 |

|

$250.74 |

|

16"

|

|

$858.93 |

|

$1,001.00 |

|

$111.87 |

|

$1,284.88 |

|

$167.46 |

|

$390.74 |

|

18"

|

|

$944.23 |

|

$1,104.83 |

|

$157.87 |

|

$1,219.35 |

|

$190.26 |

|

$443.94 |

|

20"

|

|

$1,110.65 |

|

$1,299.80 |

|

$186.42 |

|

$1,683.25 |

|

$190.26 |

|

$443.94 |

|

24"

|

|

$1,562.38 |

|

$1,823.95 |

|

$223.74 |

|

$1,876.90 |

|

$228.18 |

|

$532.42 |

Remarks:

- The joint body is available in 3 standard combinations of the (tube/cover): EPDM/EPDM, Neoprene/Neoprene, and Butyl/Butyl. The (tube/cover) are also available in a combination of the following additional materials on special order: Neoprene, EPDM, Chlorobutyl, Nitrile, Hypalon®, Viton®, Natural Rubber etc. Please see the materials table to determine what material is best for your application.

- Standard flange drilling is ANSI 150#. Also available ANSI 25/125/250/300#, Navy, DN, BS, and JIS Drilling as well as others.

- Standard flange material is carbon steel that has been treated with a rust inhibitor. Also available T-304, T-316 and other alloys.

- All Movements are non-concurrent. Contact www.rubberexpansionjoint.com to determine if your concurrent movements are acceptable.

- See the “Control Unit” page to determine if your application requires control units. Control units must be used to protect the joint if the piping is not properly anchored. Control units are sold separately from the rubber joint.

- Liners are available for the ST and STF style. Please contact www.rubberexpansionjoint.com.

Notes:

- Control unit (3 Rod) Standard

- Control unit (4 Rod) Standard

- Maximum working pressure is based on 190° F. See Temperature vs. Pressure chart for operating temperatures above 190° F.

- Test pressure is 1.5 times working pressure. Burst pressure is approximately 4 times maximum working pressure.

- The vacuum rating is based on the joint installed in the neutral length. Joints should not be installed in the extended position on vacuum applications. Please advise if the joint will be subjected to full vacuum. The use of an internal vacuum ring may be necessary.

|